Secondary Packaging Machine

- Home >>

- Access Control Devices >>

- Secondary Packaging Machine

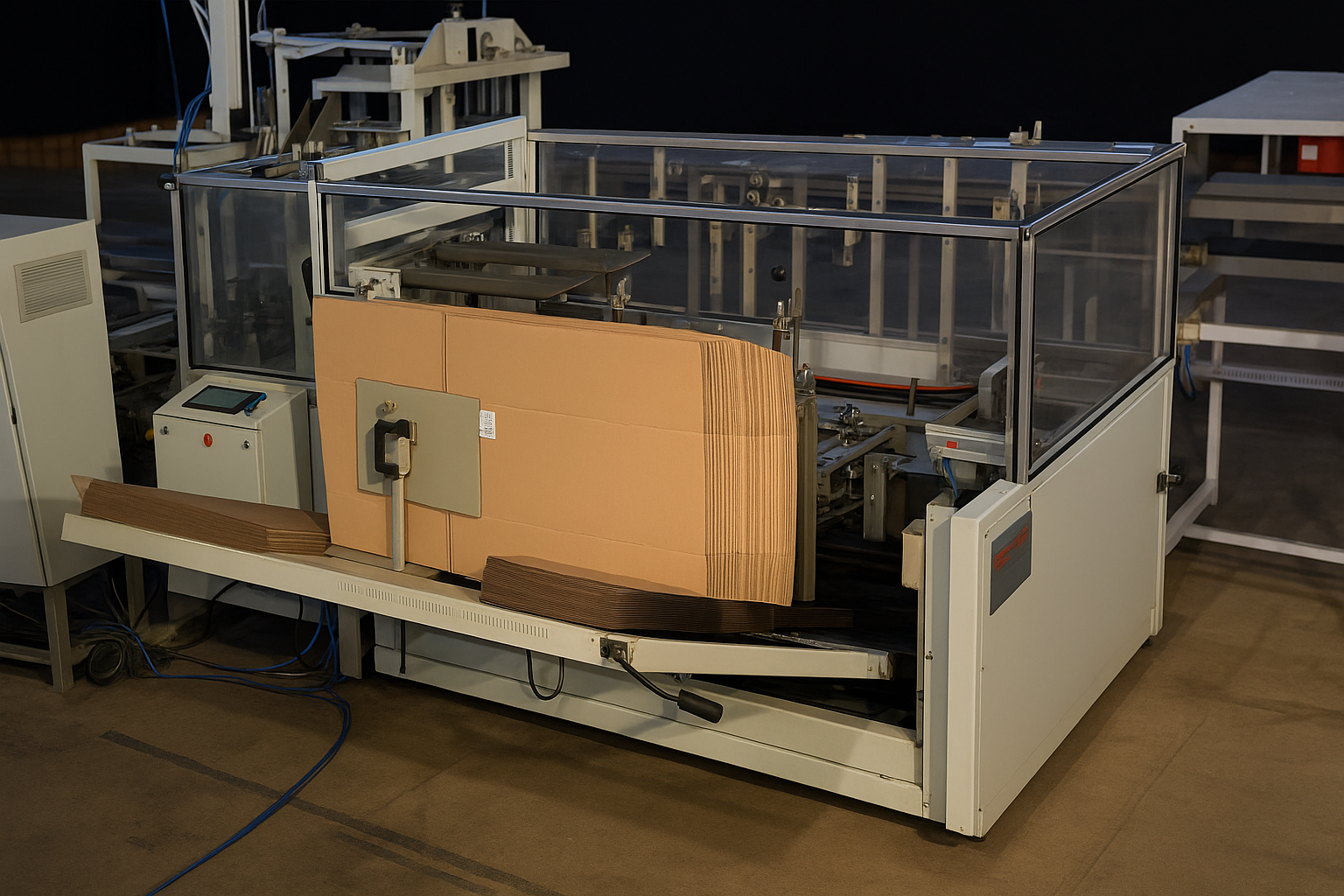

A secondary packaging machine is a type of machine used to package individual products into larger boxes, containers, or bags for easier handling and transportation when the product has already been packaged individually—think soap bars, bottles of soda, or packaged foods. NIHVA designs and installs automatic secondary packaging machines that can be customized to meet packaging needs in a variety of industries.

In rapid-paced commercial environments, reliable and efficient packaging is important to ensure products are covered, stacked, and prepared for dispatch. At NIHVA, we appreciate the growing need for seamless, smart, and automatic packaging solutions throughout manufacturing and distribution sectors. Our secondary packaging machines are designed to automate and streamline the final levels of your packaging procedure—improving productivity, consistency, and product protection.

As a leading manufacturer of automatic secondary packaging systems in India, we provide a complete range of solutions that include carton erection, product collation, case sealing, vehicle strapping, stretch wrapping, and integration with metal detection and vehicle rejector systems. These structures are broadly used in industries together with FMCG, pharmaceuticals, meals and beverages, electronics, and more.

NIHVA’s automated secondary packaging solutions are engineered for robustness, flexibility, and hygiene compliance. Whether you’re seeking out commercial-grade packaging automation for pallet loads or modular solutions for one-of-a-kind packaging designs, we deliver certified secondary packaging machines that meet international best and protection standards.

Our expert team guarantees end-to-end assistance, from requirement evaluation and system design to installation, commissioning, and lifelong service—presenting turnkey secondary packaging systems with long-term cost and reliability.

Features of our packaging solutions

- Complete automatic secondary packaging solutions, which include box erection, loading, sealing, strapping, and wrapping

- High-speed operation for continuous packaging in industrial environments

- The modular system structure allows for smooth integration with upstream and downstream manufacturing traces

- Compact, space-saving designs appropriate for both new setups and current plant layouts

- Turnkey secondary packaging structures with auto strapping and wrapping for uniform load safety and presentation

- Compatible with numerous packaging materials, including cartons, trays, film, and shrink wraps

- Inbuilt metal detection and vehicle rejector for superior product safety and compliance

Related Products

Palletizer

Palletizer is a device used for arranging and packing the individual goods on the conveyor

Frequently Asked Questions for Packaging Machine System

Secondary packaging machines are designed for intermediate packing tasks like grouping, bundling, boxing, or palletizing primary packaged products. They are used in industries such as food & beverage, pharmaceuticals, and logistics to streamline packaging before shipment or storage.

Yes. NIHVA provides fully automatic secondary packaging machines that integrate conveyor infeed, bundling, wrapping, and robotic palletizing to deliver seamless, high-throughput packaging operations

With automation, our machines enable fast case packing, case erecting, stretch-wrapping, and pallet loading, reducing manual labor and throughput times while improving handling consistency and safety.

Yes. We tailor machine configurations based on your product dimensions, packaging types, line speeds, facility layout, and integration with upstream/downstream systems. Custom options include robotic loading, vision inspection, and barcode scanning.

NIHVA ensures all machines comply with industrial safety standards. Models for food and pharma industries use hygienic materials, easy-clean surfaces, safety interlocks, emergency stops, and CE certification.